Pyroguma - Anti-Fire Mastic

Anti-fire mastic for wood and wooden products

- Fire resistance

- Patent protected

- For wood, osb, dtd

- Intumescent mastic

- For exteriors + painting

- For interiors

- Reaction for fire class B

- EI 45/minutes

Stiffening anti-fire mastic for wood and wooden products

Characteristics

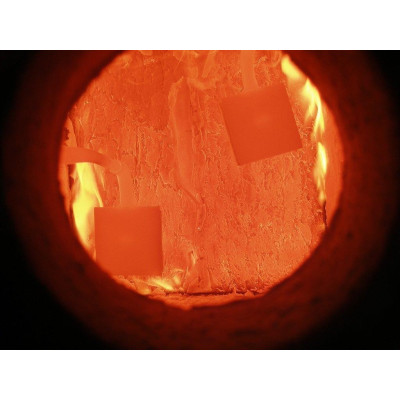

Soft mastic, having declared anti-fire resistance for wood. Anti-fire single on-foaming substance for anti-fire gap protection and wooden material conversion. During the firing process by its heating dispersion starting from + 250 °C up to +300°C it creates on the protected material surface, strong anti-fire, heating isolation layer, which extends the resistance of wooden construction against fire influence and radiant fire, together with total amount of used substance predetermines this substance as an ideal and unique protection solution.

- Class of fire reaction B-s1, d0 classification according to STN 13501-1

- Anti-fire resistance EI 45 / minutes 1-6 mm gap

- Anti-fire resistance in system OSB REI 45 /1-8 mm gap

- Anti-fire systems sealing of wooden constructions and wood

- At temperatures over +200°C it is floaming

- It prevents fire dissemination and it resists fire

- After drying it can be coated by appropriate anti-fire coatings

- Abrasive

- High adherence to different construction materials, mainly to absorbing ones

Technical Information

| Base/material: | PVAC – acrylic |

| Consistence and colour | Toxithrope white paste |

| Density | g/l: 1,38 |

| Acrylic | – PVAC water system |

| Heat resistance | -20 / + 1000 °C (after hardening) |

| For intumescency reaction | + 240 °C fire indifferent |

| Application temperature | + 5/ + 40 °C |

| Dilatation ability | ± 12,5 % |

| Period of surface layer formation | 5 minutes at 23°C |

| Drying speed | 2 mm per 3 days. |

| Maximum loadening | 250% |

| Hardening by Shore | A (3s) = 40 ± 3 |

| VOC | 0% |

Working procedure

- cut cartouche point at 45 ° angle according to gap width

- use manual or pneumatic pushing pistol

- mechanically remove spare mastic immediately

Work Safety Regulations

- keep common working hygiene, gloves, glasses

- do not eat, do not drink, do not smoke

- S2 Keep out of reach of children .

Waste dismissal

- no special regulations

- we recommend to empty cartouche wituout rest